CNC milling stands as a pinnacle of precision and innovation, leveraging computerized controls and cutting-edge tools to meticulously shape materials. The process commences with the creation of a 3D model using Computer-Aided Design (CAD) software, which is then translated into G-code instructions directing the CNC machine’s precise movements. Equipped with various cutting tools, the CNC milling machine executes these instructions, enabling the creation of intricate components with unparalleled accuracy.

What sets us apart is the seamless integration of advanced technology and the expertise of skilled machinists. Our CNC milling process ensures both precision for intricate designs and efficiency for diverse production scales. Sustainability is a paramount consideration, with a commitment to resource conservation and waste reduction embedded in our practices.

Through a continuous pursuit of improvement, innovation, and a steadfast commitment to customer satisfaction, our CNC milling process not only delivers components of exceptional quality but also transforms design concepts into tangible realities with a focus on environmental responsibility.

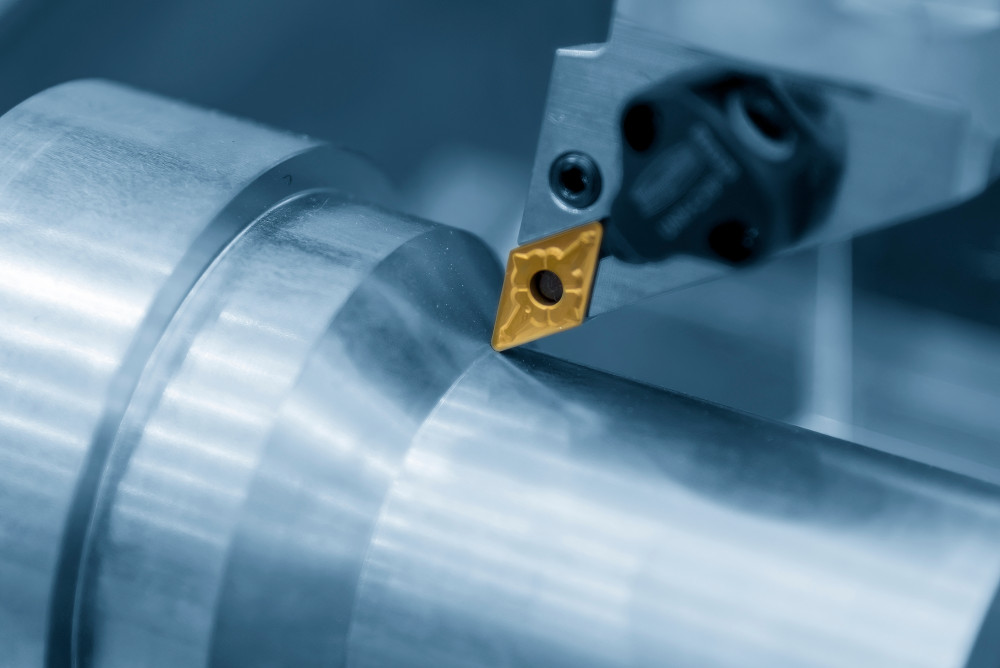

CNC turning is a cutting-edge machining process that involves the precise rotation of a workpiece while a stationary cutting tool shapes it into the desired form. This process, guided by computerized controls, enables the creation of intricate cylindrical components with exceptional accuracy and efficiency.

In the CNC turning process we utilizes Computer-Aided Design (CAD) software to generate a detailed 3D model of the desired part. This digital representation is then translated into G-code, providing precise instructions for the CNC turning machine. The machine, equipped with a variety of cutting tools, then systematically removes material from the rotating workpiece, creating finely crafted components.

What sets our CNC turning apart is the integration of advanced technology, skilled machinists, and a commitment to delivering superior results. From prototyping to large-scale production runs, our CNC turning process ensures the consistent production of components with tight tolerances and intricate designs. The focus on precision, efficiency, and technological innovation defines our approach to CNC turning at Mind4 MFG.

Short order expedited machining signifies a commitment to providing swift and efficient machining solutions to meet urgent and time-sensitive needs. This specialized service is designed to deliver precision and quality in a shorter timeframe, catering to the dynamic requirements of clients who demand rapid production of components without compromising on accuracy. We collaborate with inventors, entrepreneurs, engineers, and scientists, fostering a creative environment for development efforts that thrive on precision and efficiency.

In the short order expedited machining process, we leverage a dedicated approach that streamlines operations, accelerates production timelines, and ensures prompt delivery. This service is particularly beneficial for projects with tight deadlines, enabling clients to receive high-quality machined parts quickly and reliably.

What sets us apart in short order expedited machining is our ability to balance speed with precision. Whether it’s prototyping or urgent production runs, our skilled machinists, coupled with cutting edge technology, work collaboratively to ensure that each component meets the required specifications while adhering to the accelerated timeline.

Fixture design and creation play a crucial role in ensuring efficient and reliable machining processes. Our expertise in fixture design involves crafting customized solutions that optimize the production of precision components. Fixtures serve as specialized devices that securely hold and position workpieces during machining, contributing to consistency and accuracy. Mind4 MFG’s commitment to fixture design and creation reflects our dedication to maximizing efficiency, maintaining tight tolerances, and delivering reliable results in every machining project. Through meticulous planning and innovative solutions, our fixture design process is an integral part of our overall approach to achieving excellence in precision machining.

Precision welding represents a pinnacle of craftsmanship, employing advanced techniques such as MIG, TIG, and brazing to ensure the highest standards of strength, durability, and precision in welded components. Our skilled welders bring together expertise and cutting-edge technology to seamlessly join materials, creating robust and intricate parts that meet the most demanding specifications.

In the precision welding process, we utilize MIG (Metal Inert Gas) welding for efficient and strong welds, TIG (Tungsten Inert Gas) welding for precision and control in delicate applications, and brazing for joining dissimilar metals with precision and minimal heat impact. This diverse set of welding techniques allows us to cater to a wide range of materials and project requirements.

What distinguishes Mind4 MFG’s precision welding is our unwavering commitment to delivering exceptional quality. From prototypes to production runs, our welding process is characterized by meticulous attention to detail, a focus on precision, and the integration of the latest welding technologies. Whether it’s MIG, TIG, brazing, or other welding methods, we ensure that each welded component meets stringent standards for both functionality and aesthetics.

Finishing processes adds the perfect touch to machined components, enhancing both aesthetics and durability. These processes include anodizing, plating, powder coating, and more, ensuring that the final products not only meet precise specifications but also boast exceptional visual appeal. Our commitment to finishing goes beyond functionality, offering a comprehensive range of surface treatments to cater to diverse materials and project requirements. With a focus on quality craftsmanship and attention to detail, our finishing services elevate the overall quality and longevity of machined components, providing clients with a complete and polished solution.

724.953.3546

jeremy@mind4mfg.com

3154 Ligonier Street Latrobe PA 15650